AUTOFIBER-5

To push

printing

further.

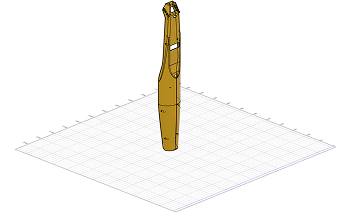

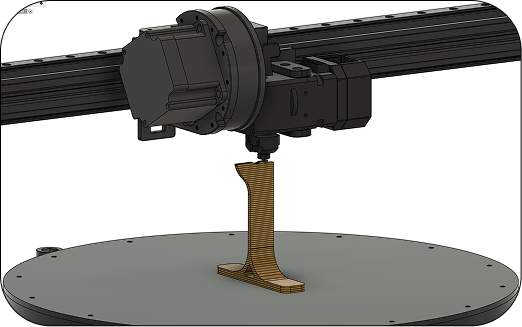

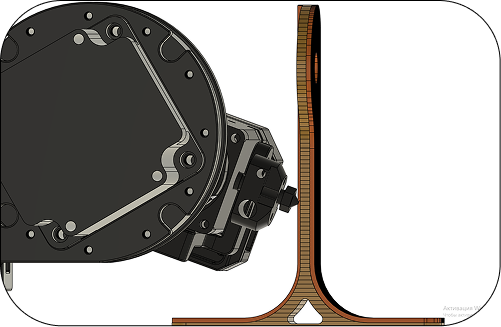

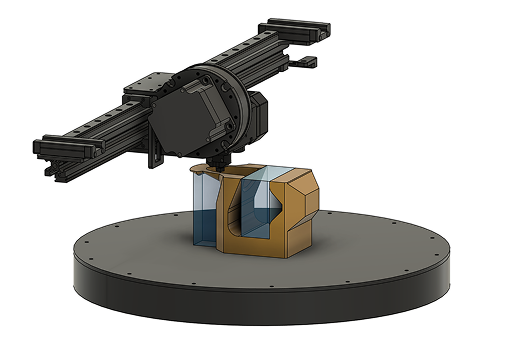

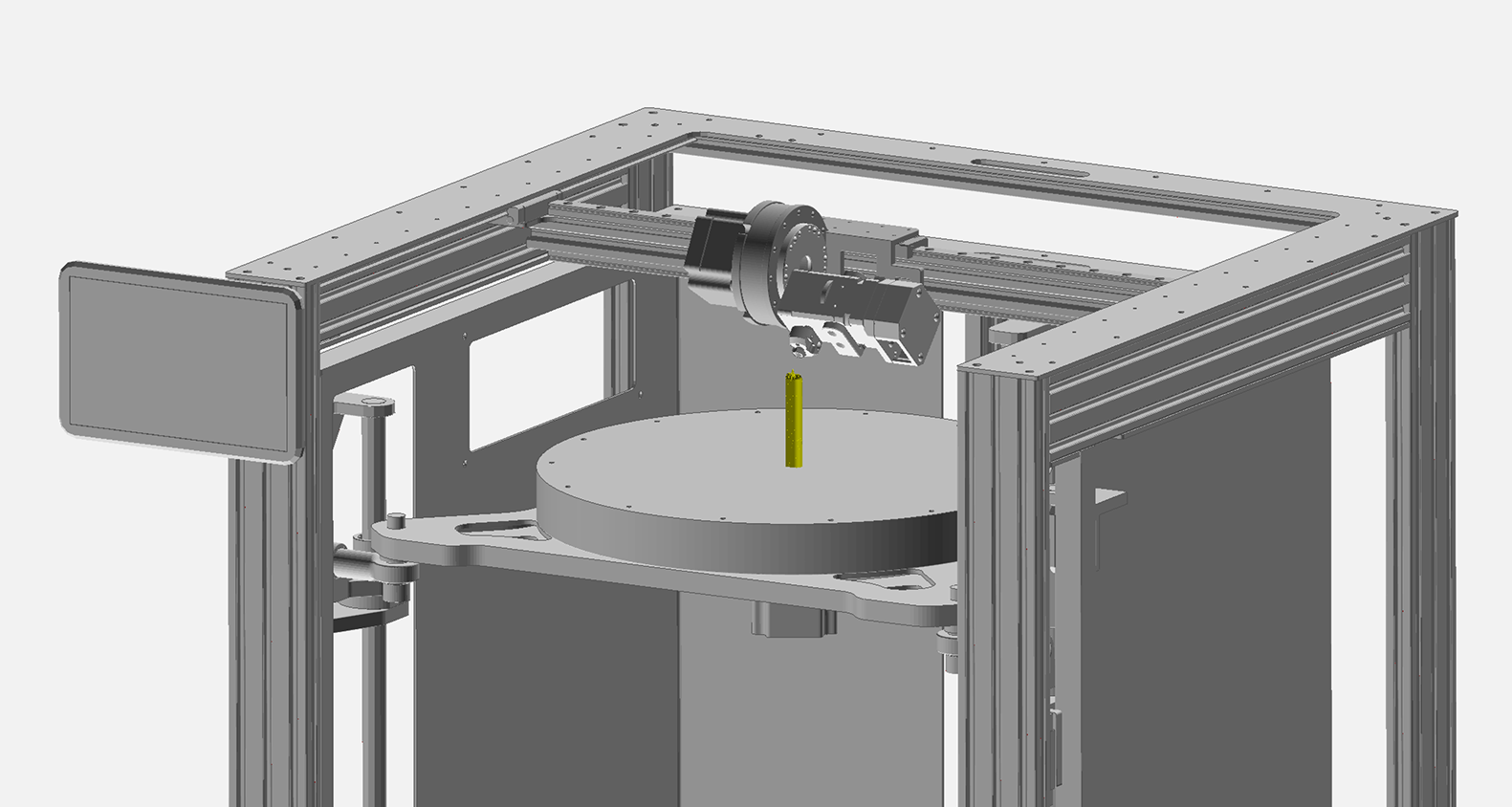

Our 5-axis tailor for your composite parts

CHANGE THE WAY

YOU CREATE

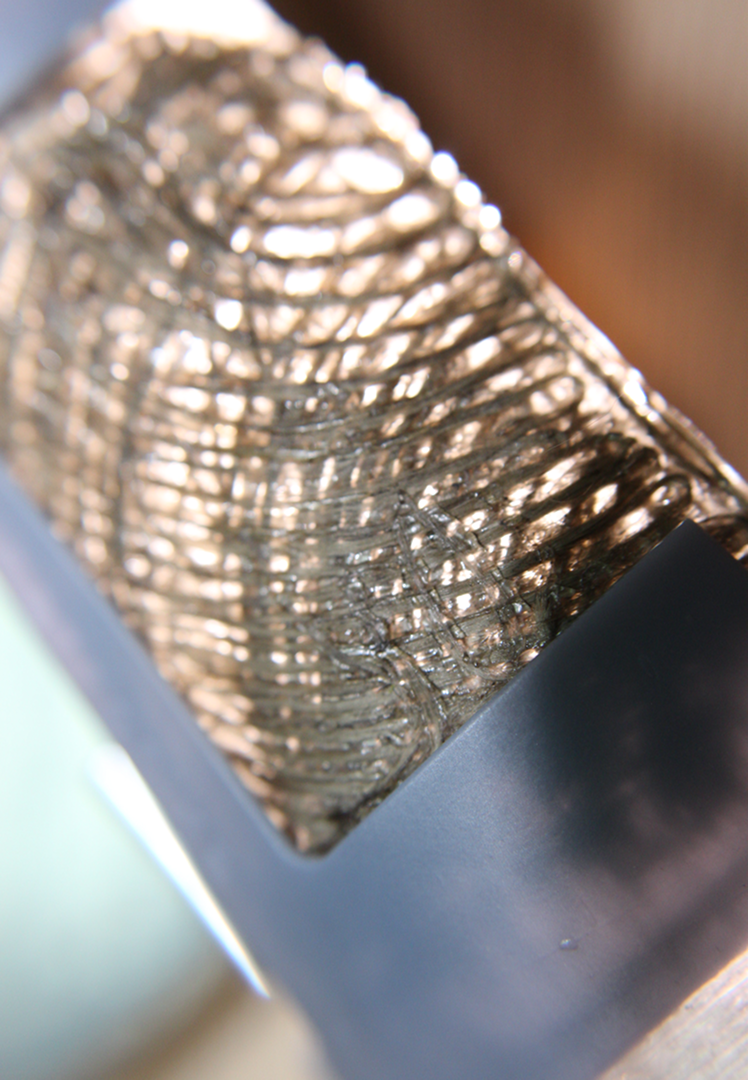

Make industrial-grade continuous composites in one process.

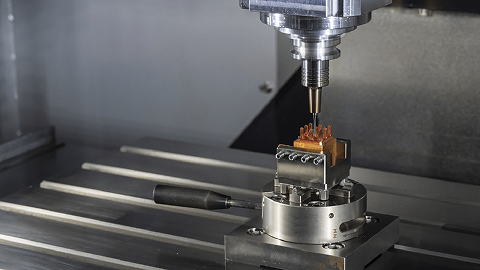

Able to print refractory polymers (PEEK,

ULTEM).

BUILT FOR

MORE

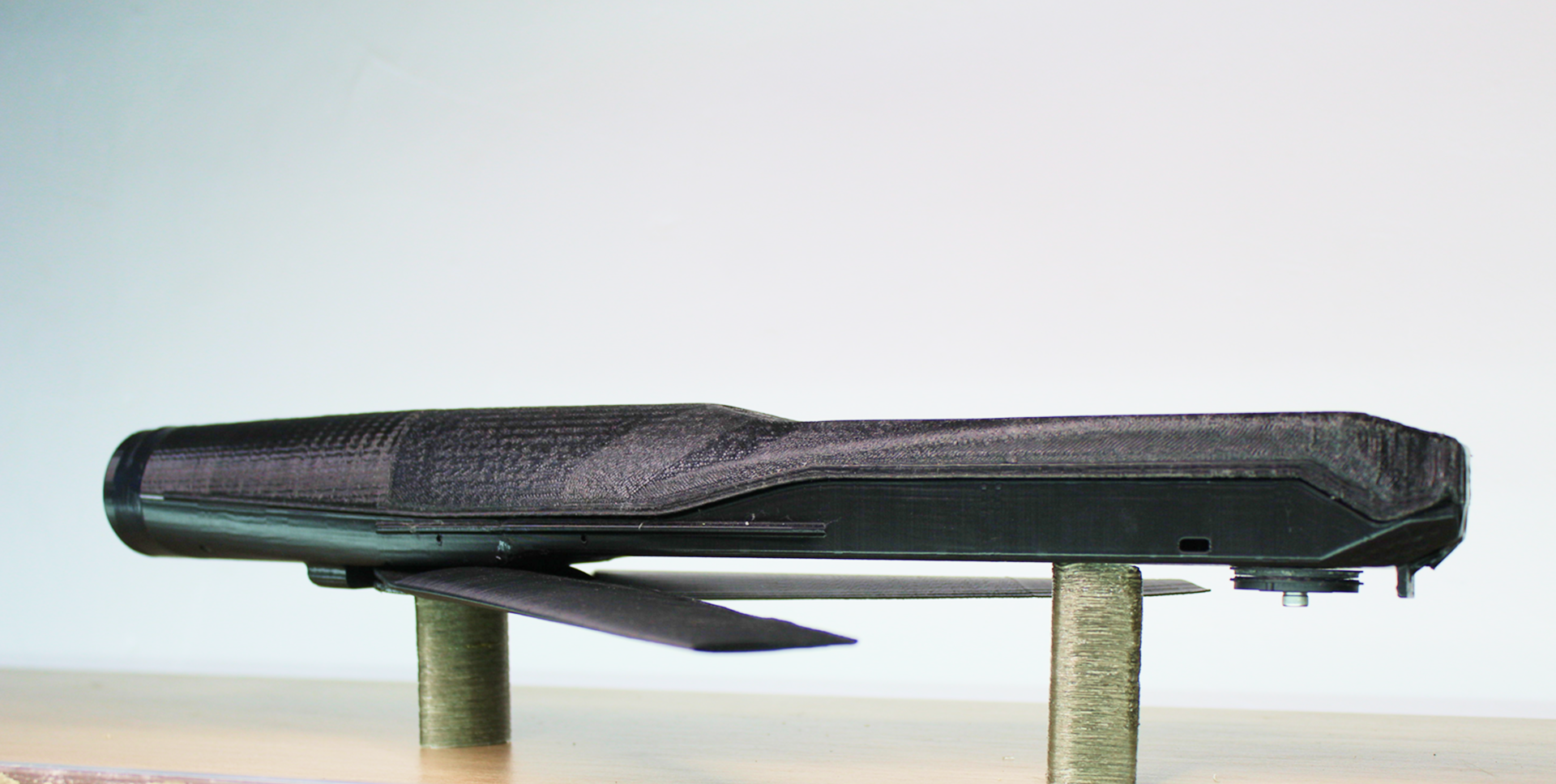

Workspace: diameter 300x700 mm

in

multi-axis mode

For your big concepts.

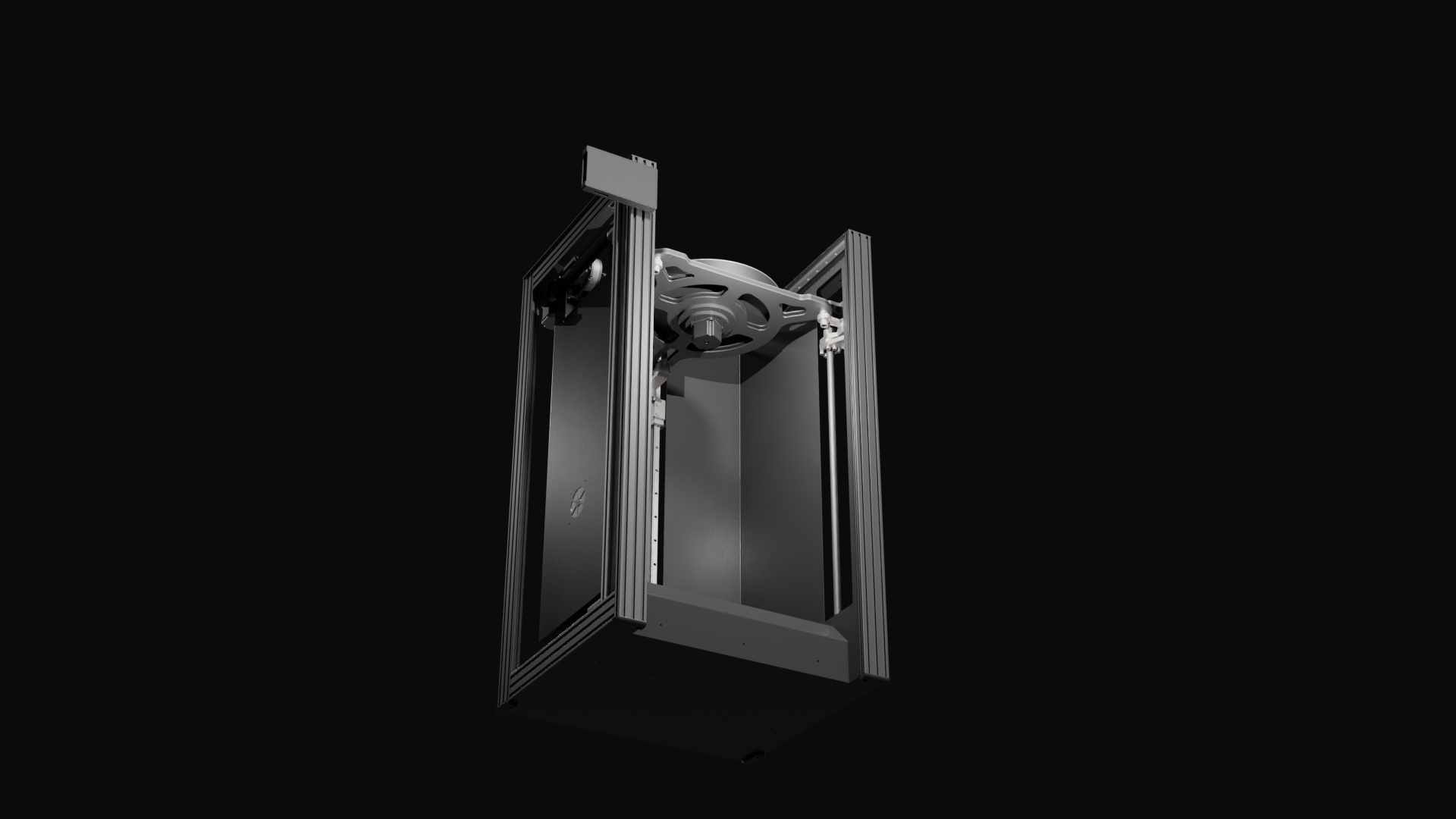

ROBUSTNESS

MATTERS

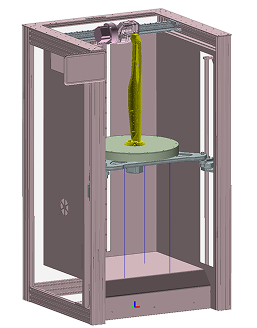

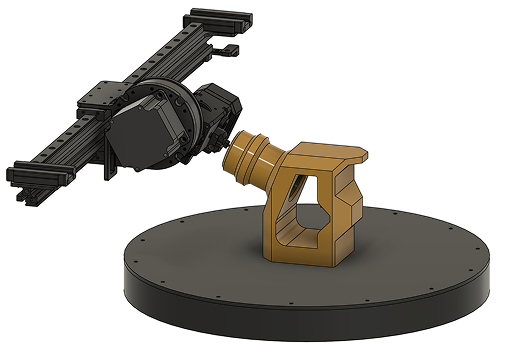

Custom 5-axis

kinematic scheme

along with precision

linear and rotational

drives.

NO COMPROMISES

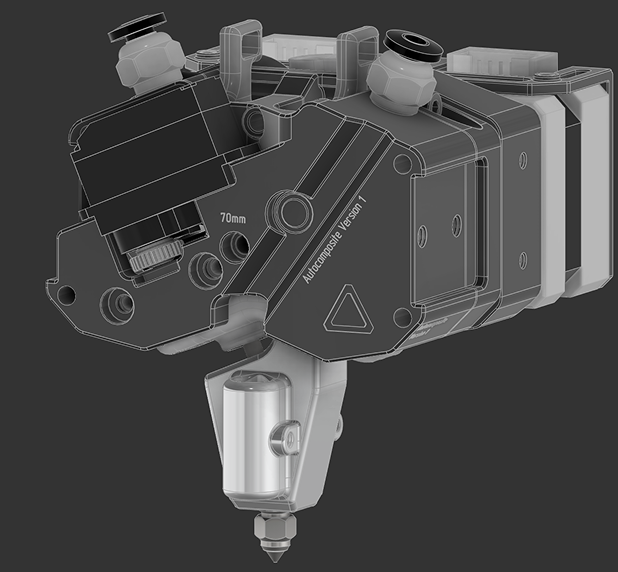

- Water component cooling,

compressed

air printed model cooling.

- Full-auto buildplate leveling and

temperture

expansion compensation.

- Active ringing compensation.

- Active heated material box.